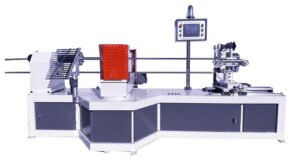

Home » Automatic Paper Tube Making Machine (Two Heads)

Automatic Paper Tube Making Machine (Two Heads Machine)

The Automatic Paper Tube Making Machine (Two Heads Machine) is designed for the mass production of paper tubes and cores. This machine is equipped with two mandrels, enabling simultaneous or alternating production, which significantly increases efficiency and reduces downtime. It’s widely used in packaging, textile, paper, and other industries that require high-quality, precise paper tubes.

PS-2060C CNC paper tube machine

Technical Parameters | |

Ply qty of paper | 3-8 ply |

Diameter of core | 20mm–60mm |

Thickness of core | 1mm–5mm |

Winding head | Double heads single belt |

Cutting method | Single servo multi-knife online arbitrary cutting |

Glue adding method | Single-sided /double-sided gluing |

Length-control-method | Encoder pulse fixed length |

Synchronous control | Servo synchronous tracking cutting |

Belt diagonal | electric |

Paper tape automatically supplied with lubrication | automatic |

Power | 3.7KW*2 |

PLC controller | Taiwan/Taida |

Human-computer-interface | Color touch screen |

Input Power | 380V three-phase four-wire (other voltage customization) |

Number of operators | 1-2 workers |

Core winding speed | 3-30m/min |

Size | 2800mm×1800mm×1500mm |

Total Weight | 1300kg |

PS-2060C CNC multi-knife paper tube machine

Technical Parameters | |

Ply qty of paper | 3-8 ply |

Diameter of core | 20mm–60mm |

Thickness of core | 1mm–5mm |

Winding head | Double heads single belt |

Cutting method | Single servo multi-knife online arbitrary cutting |

Glue adding method | Single-sided /double-sided gluing |

Length-control-method | Encoder pulse fixed length |

Synchronous control | Servo synchronous tracking cutting |

Belt diagonal | electric |

Paper tape automatically supplied with lubrication | automatic |

Power | 3.7KW*2 |

PLC controller | Taiwan/Taida |

Human-computer-interface | Color touch screen |

Input Power | 380V three-phase four-wire (other voltage customization) |

Number of operators | 1-2 workers |

Core winding speed | 3-30m/min |

Size | 3500mm×1500mm×1550mm |

Total Weight | 1300kg |

PS-2150B CNC Paper Core Making Machine

Technical Parameters | |

Ply qty of paper | 3-16 ply |

Diameter of core | 20mm–150mm |

Thickness of core | 1mm–6mm |

Winding head | Double heads single belt |

Cutting method | Single round knife cutting,without resistance |

Glue adding method | Single-sided /double-sided gluing |

Length-control-method | photoelectric |

Synchronous control | pneumatic |

Belt diagonal | electric |

Power | 5.5KW |

PLC controller | Taiwan/Taida |

Human-computer-interface | Color touch screen |

Input Power | 380V three-phase four-wire (other voltage customization) |

Number of operators | 1-2 workers |

Core winding speed | 3-20m/min |

Size | 2900mm×1900mm×1920mm |

Total Weight | 1800kg |

PS-2150C multi-knife online cutting CNC paper tube machine

Technical Parameters | |

Ply qty of paper | 3-16 ply |

Diameter of core | 20mm–120mm |

Thickness of core | 1mm–8mm |

Winding head | Double heads single belt |

Cutting method | Single servo multi-knife online arbitrary cutting |

Glue adding method | Single-sided /double-sided gluing |

Length-control-method | Encoder pulse fixed length |

Synchronous control | Server synchronous tracking and cutting |

Belt diagonal | electric |

Host swing angle | electric |

PLC controller | automatic |

Power | 7.5KW |

PLC controller | Taiwan/Taida |

Human-computer-interface | Color touch screen |

Input Power | 380V three-phase four-wire (other voltage customization) |

Number of operators | 1-2 workers |

Core winding speed | 3-30m/min |

Size | 4500mm×1800mm×1750mm |

Total Weight | 3200kg |

PS-2150C CNC paper tube machine

Technical Parameters | |

Ply qty of paper | 3-16 ply |

Diameter of core | 20mm–120mm |

Thickness of core | 1mm–8mm |

Winding head | Double heads single belt |

Cutting method | Single servo single circular knife without resistance cutting |

Glue adding method | Single-sided /double-sided gluing |

Length-control-method | Encoder pulse fixed length |

Synchronous control | Server synchronous tracking and cutting |

Belt diagonal | electric |

Host swing angle | electric |

PLC controller | automatic |

Power | 7.5KW |

PLC controller | Taiwan/Taida |

Human-computer-interface | Color touch screen |

Input Power | 380V three-phase four-wire (other voltage customization) |

Number of operators | 1-2 workers |

Core winding speed | 3-30m/min |

Size | 4000mm×2000mm×1950mm |

Total Weight | 2500kg |

PS-2150D CNC paper tube machine

Technical Parameters | |

Ply qty of paper | 3-16 ply |

Diameter of core | 20mm–120mm |

Thickness of core | 1mm–8mm |

Winding head | Double heads single belt |

Cutting method | Double servo single circular knife without resistance cutting |

Glue adding method | Single-sided /double-sided gluing |

Length-control-method | Encoder pulse fixed length |

PS-2150D CNC paper tube machine (Plus)

Technical Parameters | |

Ply qty of paper | 3-16 ply |

Diameter of core | 20mm–500mm |

Thickness of core | 1mm–4mm |

Winding head | Double heads single belt |

Cutting method | Double servo single circular knife without resistance cutting |

Glue adding method | Single-sided /double-sided gluing |

Length-control-method | Encoder pulse fixed length |

Synchronous control | Server synchronous tracking and cutting |

Belt diagonal | electric |

Host swing angle | electric |

PLC controller | automatci |

Power | 7.5KW |

PLC controller | Taiwan/Taida |

Human-computer-interface | Color touch screen |

Input Power | 380V three-phase four-wire (other voltage customization) |

Number of operators | 1-2 workers |

Core winding speed | 3-30m/min |

Size | 4000mm×2000mm×1950mm |

Total Weight | 3200kg |

PS-2150S CNC Paper tube machine

Technical Parameters | |

Ply qty of paper | 3-16 ply |

Diameter of core | 20mm–150mm |

Thickness of core | 1mm–8mm |

Winding head | Double heads single belt |

Cutting method | Single servo single circular knife without resistance cutting |

Glue adding method | Single-sided /double-sided gluing |

Length-control-method | Encoder pulse fixed length |

Synchronous control | Server synchronous tracking and cutting |

Belt diagonal | electric |

Host swing angle | electric |

PLC controller | automatic |

Power | 11 KW |

PLC controller | Taiwan/Taida |

Human-computer-interface | Color touch screen |

Input Power | 380V three-phase four-wire (other voltage customization) |

Number of operators | 1-2 workers |

Core winding speed | 3-30m/min |

Size | 4000mm×2000mm×1950mm |

Total Weight | 2800kg |